MISION

Generate economic value with social responsibility by offering solutions and projects for the transformation of materials handling plastic and POP according to the needs of each client, taking advantage of the recovered material supply chains to be leaders in cost.

VISION

Being the largest plastic transformer in America, specialized in material handling products, doubling the value of the business every 5 years.

VALUES

- Teamwork.

- Operational excellence.

- Passion that guides

our clients. - Communication.

- Innovation.

What do we do at PTM?

At PTM we are dedicated to providing solutions and plastic transformation projects tailored to our clients, mainly in industries such as:

Extursión

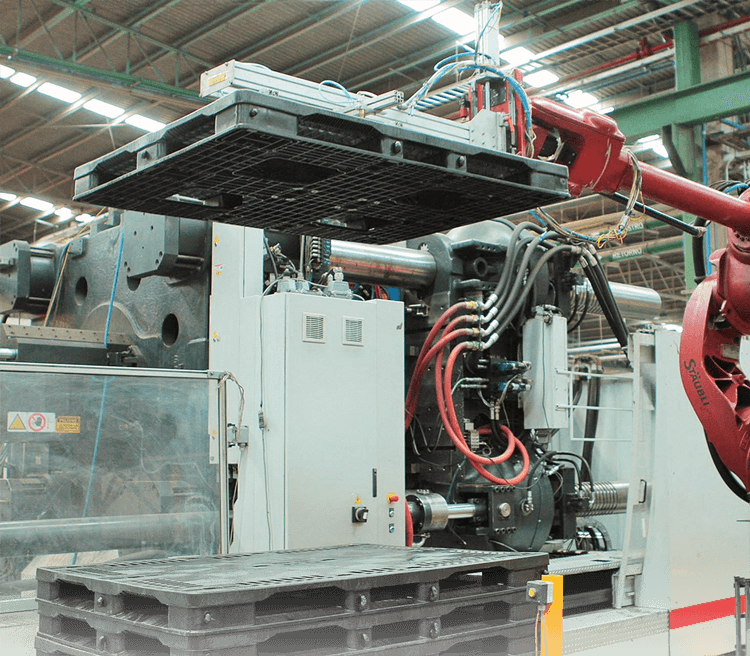

Injection

This process consists of heating the thermoplastic above its melting point and then injecting it under pressure into a mold. Once in it, we remove the heat, allowing the plastic to solidify to form the final product.

Soplado

This process uses air pressure to expand a thermoplastic “sleeve” already softened in the mold cavity.

Termoformado

In this process, a thermoplastic sheet is heated until it softens. Then, through a mechanical assistant, vacuum action or both, it adapts to the shape of a mold. Once in it, the heat is removed allowing the plastic to solidify to form the final product.

PTM IN SUMMARY …

We are leaders in the manufacture of plastic boxes for the beverage industry in Latin America.

We provide comprehensive solutions and develop plastic transformation projects.

We work with +1,000 collaborators committed to your project.

We maintain constant R&D, implement cutting-edge technology and generate sustainable and profitable products.

Our model is based on 3 pillars:

-Innovative design.

-Operational Excellence.

-Sustainability.

We transform +35,000 tons of plastic resins per year.

Facilities

Our experience in design and engineering, combined with the latest technology in our production process, allows us to transform any idea into a highly functional, profitable and sustainable product.

We work with:

- Injection machines from 700 to 2,300 tons, with plasticization between 3 and 23 kg.

- Single and triple layer extruder.

- Single station and rotary thermoformers.

- Double screw pelletizer.

- Mills and rippers from 1,000 to 2,000 kg / h.

- Material washing lines.

- Material mixing and homogenization lines.

- Laboratory for characterization of materials.

- Mechanical testing laboratory for product performance.

Our history

Proud to belong to FEMSA, our story begins in 1976. We are dedicated to providing solutions and developing plastic transformation projects, transforming more than 30,000 tons of resin per year.